| A look at the Clarkson Mark1 Spindle Bearings |

↓ I smeared a small amount of LM grease into the race, taking care not to overpack the bearing.

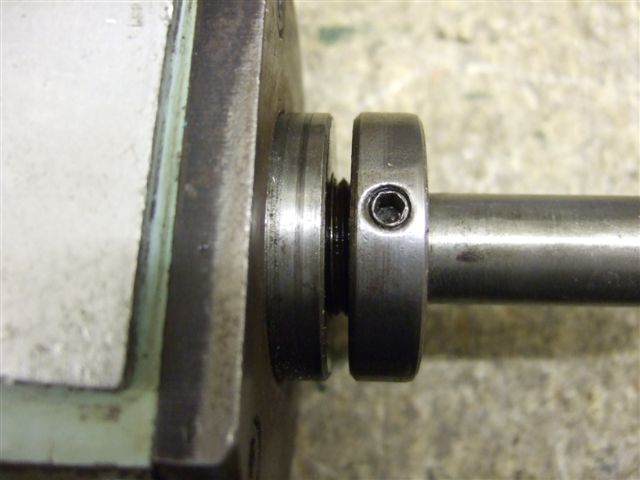

↓ MARK 2 - The adjusting collar can be unscrewed once the socket set screw is slackened.

↓ MARK 2 - needle rollers