| Clarkson Mark 1 Tool and Cutter Grinder - Relieving End Teeth - End Mill |

↓ The new adapter bush dimensions are:- length = 1.5inch

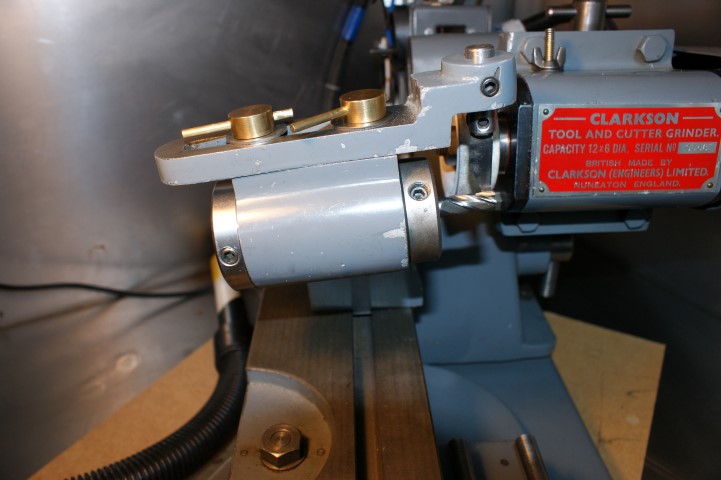

↓ There is a groove in the cup wheel, and that needs to be dressed out.

↓ The wheel is now flat and dressed.

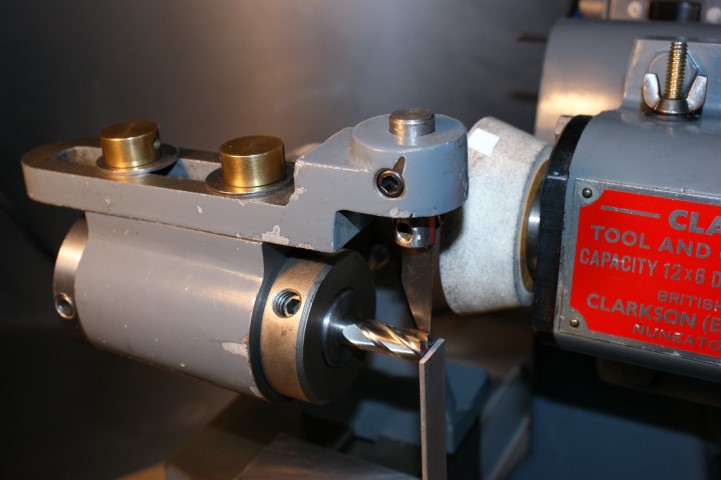

↓ The cutter is located in the adapter bush.

↓ The adapter bush is inserted into the holder.

↓ The cross hole in the adapter bush is lined up with the threaded hole in the holder.

↓ The cutter is positioned, taking care to ensure that the ball does not bear down on the threaded end of the cutter (if threaded end is present).

↓ The hex set screw is inserted in the threaded hole of the holder, and is gently and carefully tightened, to bring the assembly together.

↓ A collar is fitted.

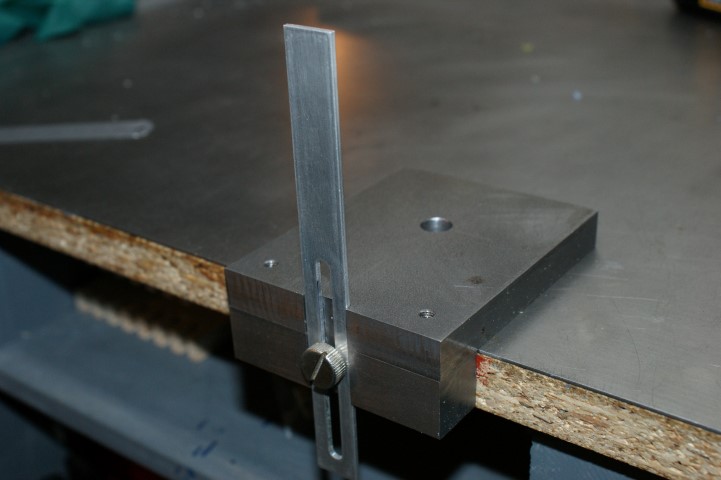

↓ The slotted guide can be moved up or down to suit the situation.

↓ The teeth are lined up to the end of the slotted guide.

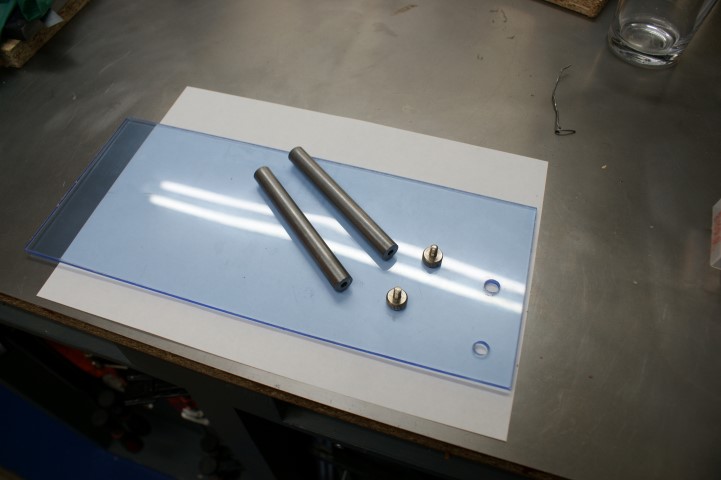

↓ Here are the parts of the cutter setter.

↓ Once the teeth are roughly parallel with the table, the toothrest bracket and toothrest finger are adjusted and secured so that the end mill is prevented from turning.

↓ Make sure the bracket is secure and will not come loose during the whole operation.

↓ The table position after it was set over by a little bit.

↓ The table position after it was set over by a lot.

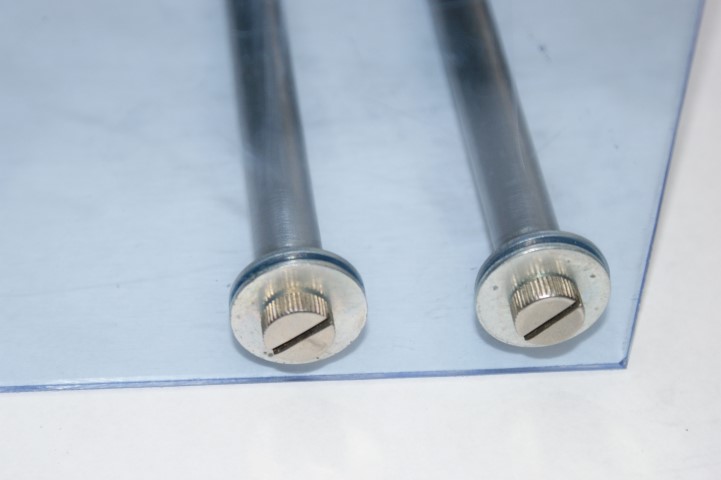

↓ The two M5 thumb screws.

↓ It needed some large washers to spread the load.

↓ The two 0.5inch bars fit in the lower toothrest mounting block.

Now, my layers of eye protection are ... the shield next to the grinding wheel, then the optivisor lenses, then my safety glasses, then my seeing glasses.

The next thing I need to learn is to regrind the primary and secondary faces on the flutes. It looks like I need to get a 6 inch wheel for that operation.