| Fitting a new motor on the Clarkson Mark1 - Single Phase |

↓ Here is the temporary wooden plate that is being replaced here.

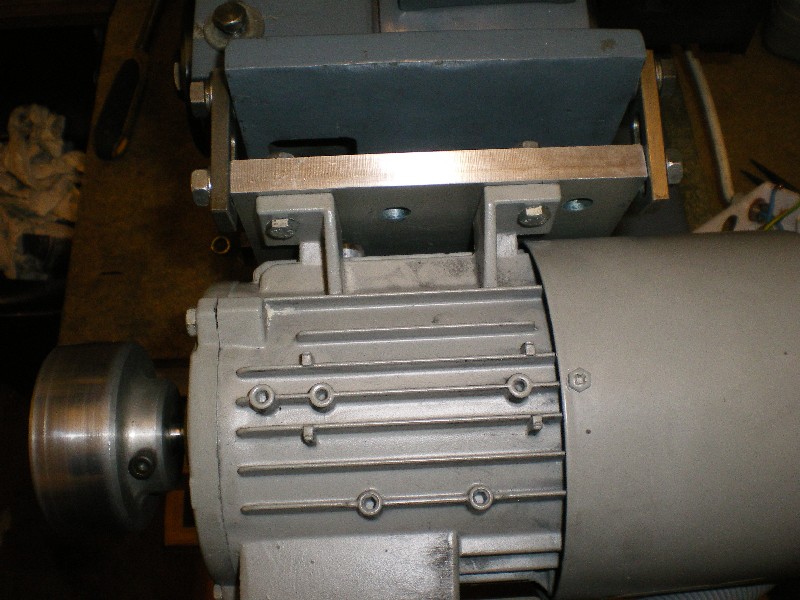

I milled the edges to clean them up.

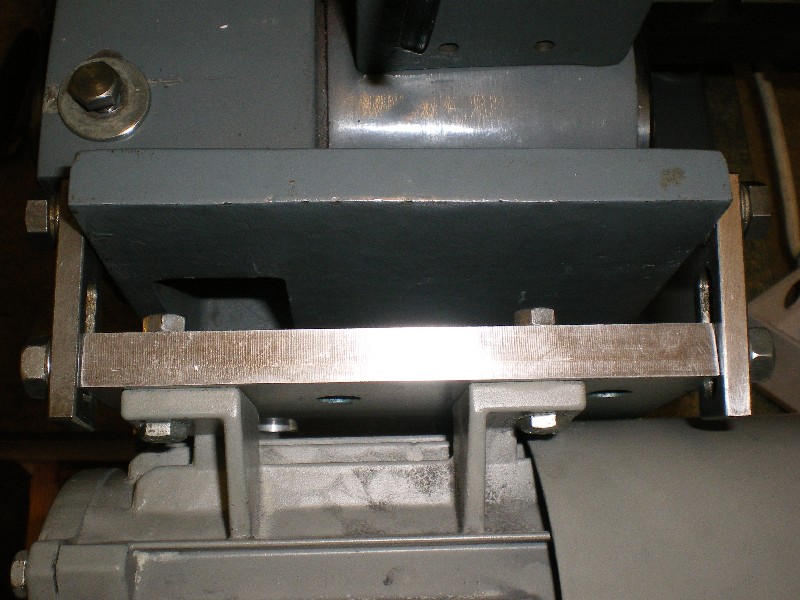

The slot after machining. Aah, that's better, not perfect, but much better.

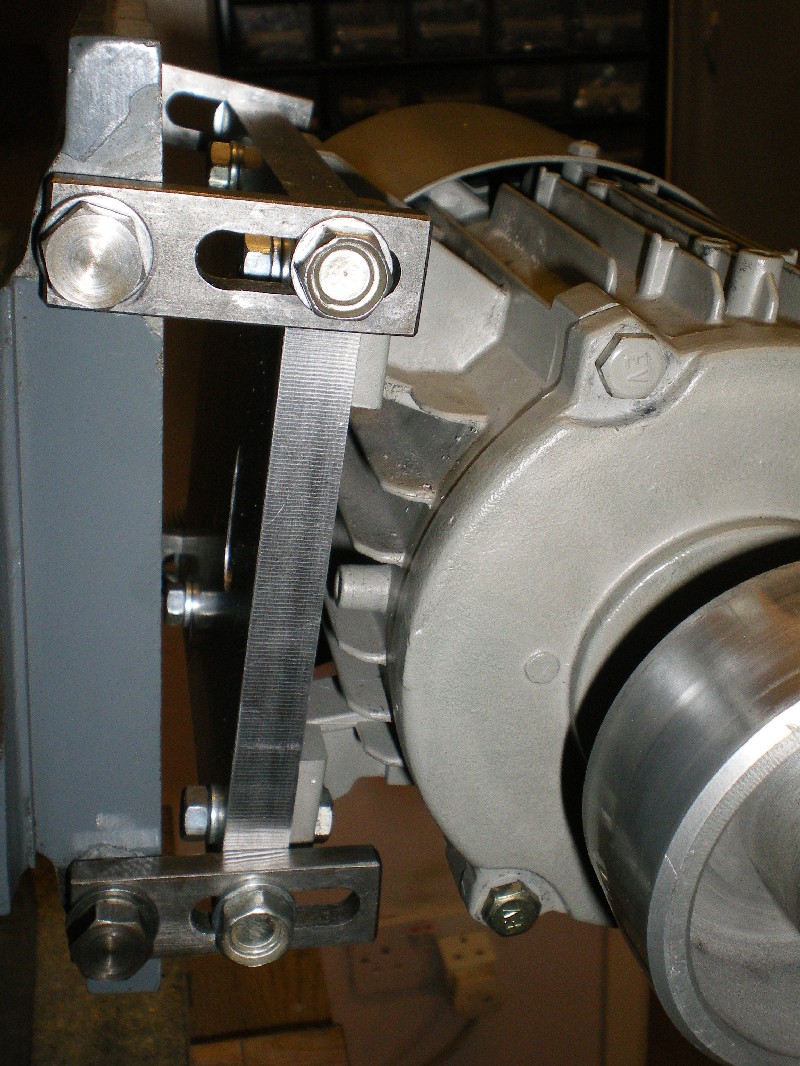

↓ The plate is fitted to the adjusting lugs.

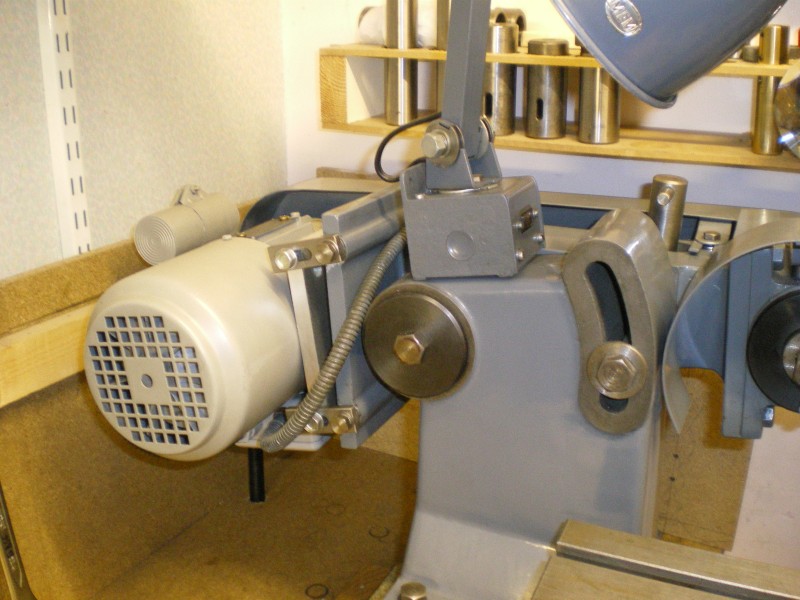

↓ The motor is fitted to the plate.

↓ The new belt is tensioned by correctly positioning the motor plate in the slots of the four adjusting lugs.

Here is the rough side of the new belt.

The new belt is about 1.5 inches shorter than the old belt.

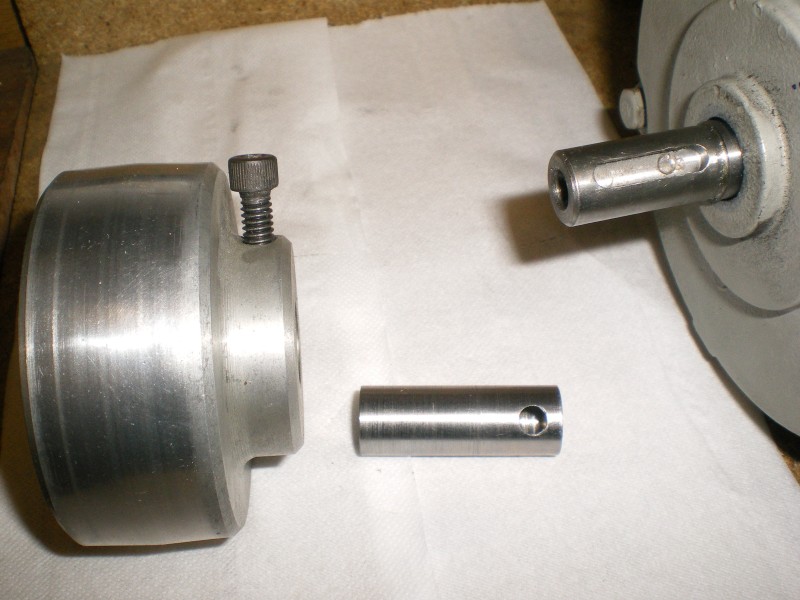

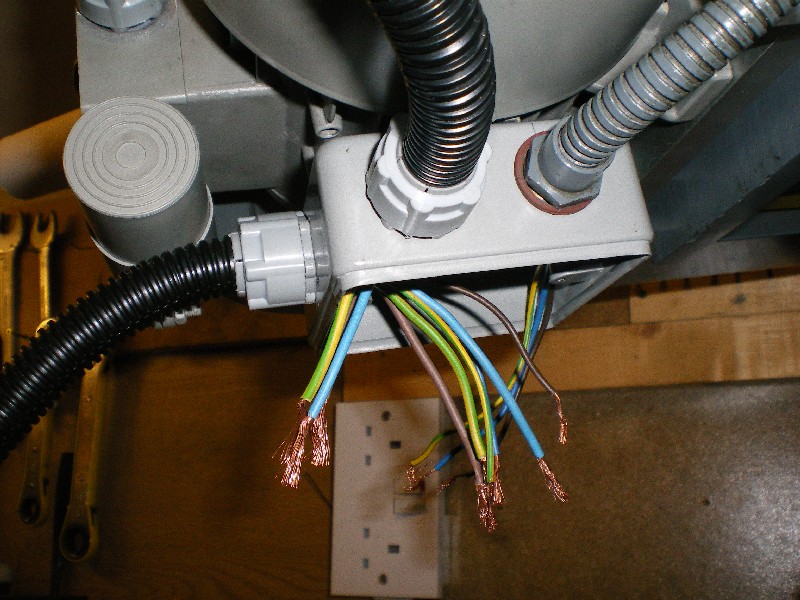

↓ I tapped two lugs on the motor. The junction box will be fixed to these lugs.

↓ The metal junction box is secured to the underside of the motor with two M4 screws.

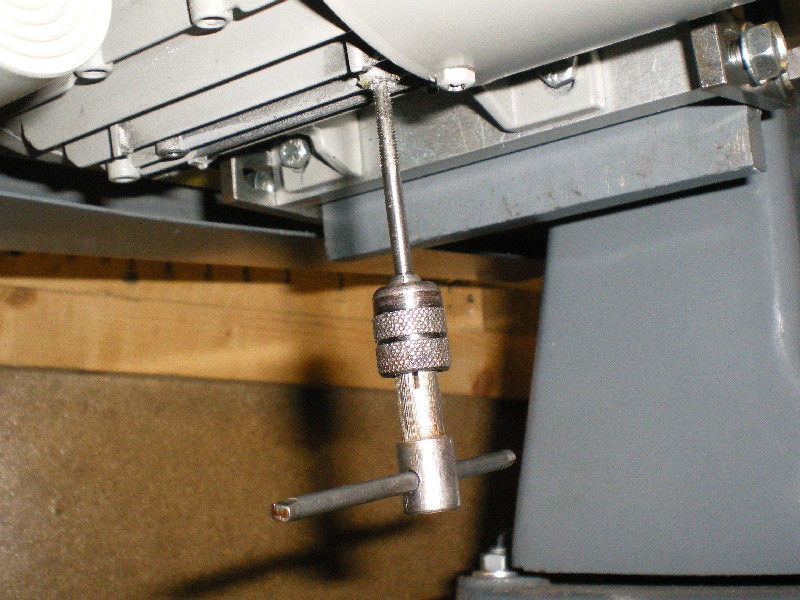

↓ Here is the Mem conduit entering the junction box on the underside of the motor.

↓ I bought the plastic conduit and fittings from Maplins.

↓ The power feed conduit is routed through a hole in the top of the bench.