| Fitting a new motor on the Clarkson Mark1 - 3 Phase |

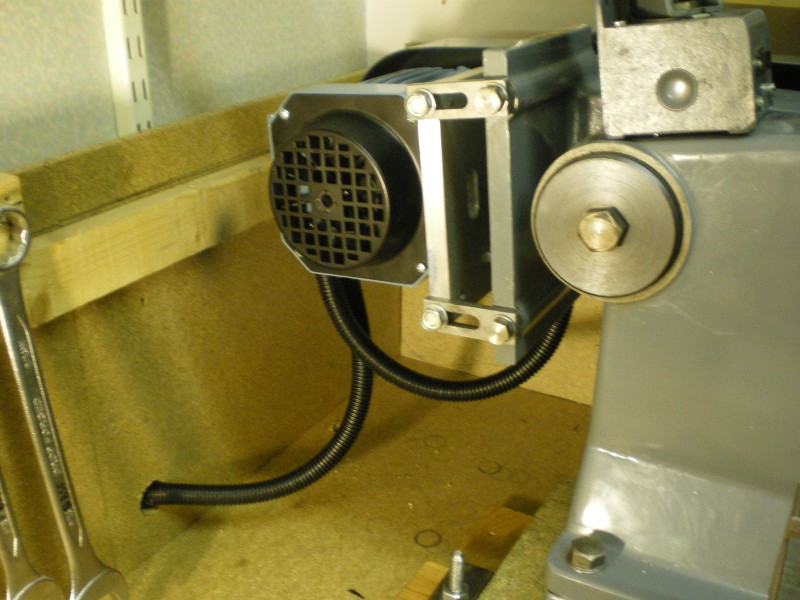

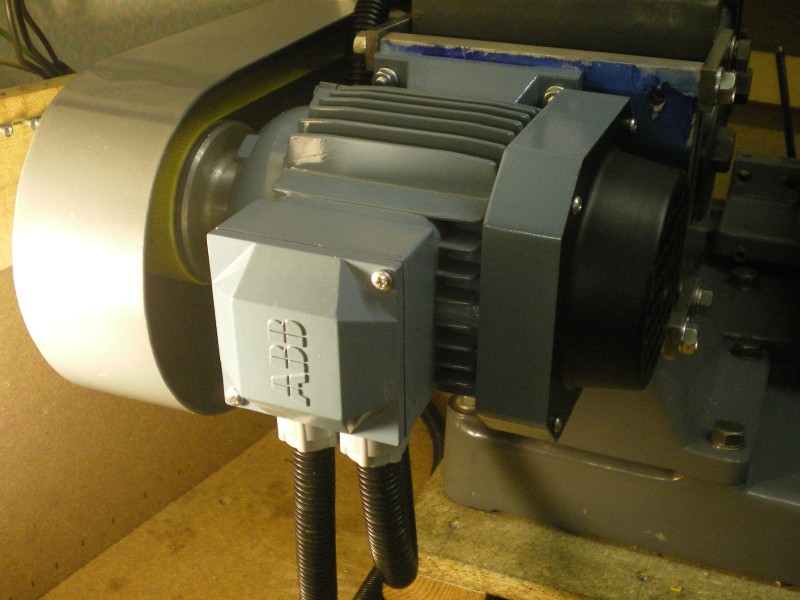

↓ Here is the 3 Phase motor after fitting. It is a small motor.

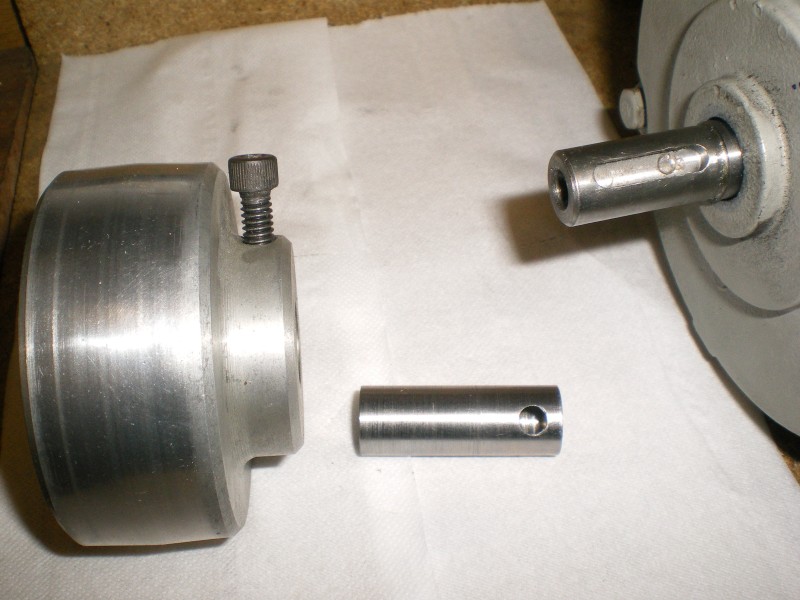

↓ In the lathe, I turned down the outside of the sleeve to around 15.8mm diameter, until it would just fit inside the bore of the pulley. I bored the sleeve to around 10.96mm diameter, until it would just slip over the motor shaft.

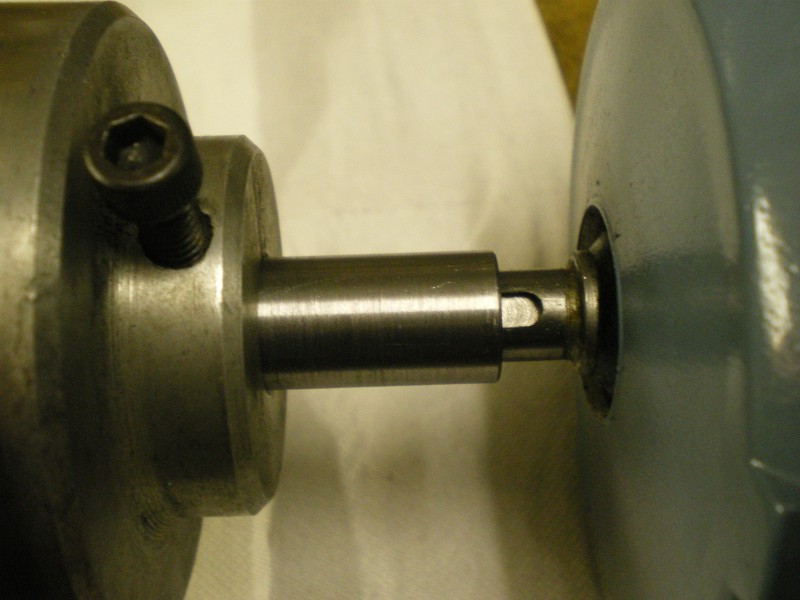

↓ Trying the sleeve in the bore of the pulley and over the motor shaft. The hole for the holding screw has not been drilled yet.

↓ I replaced the 1/4 inch BSW bolt with a 1/4 inch BSW socket set screw (grub screw). I turned down the end of the socket set screw so it was a nice fit in the keyway.

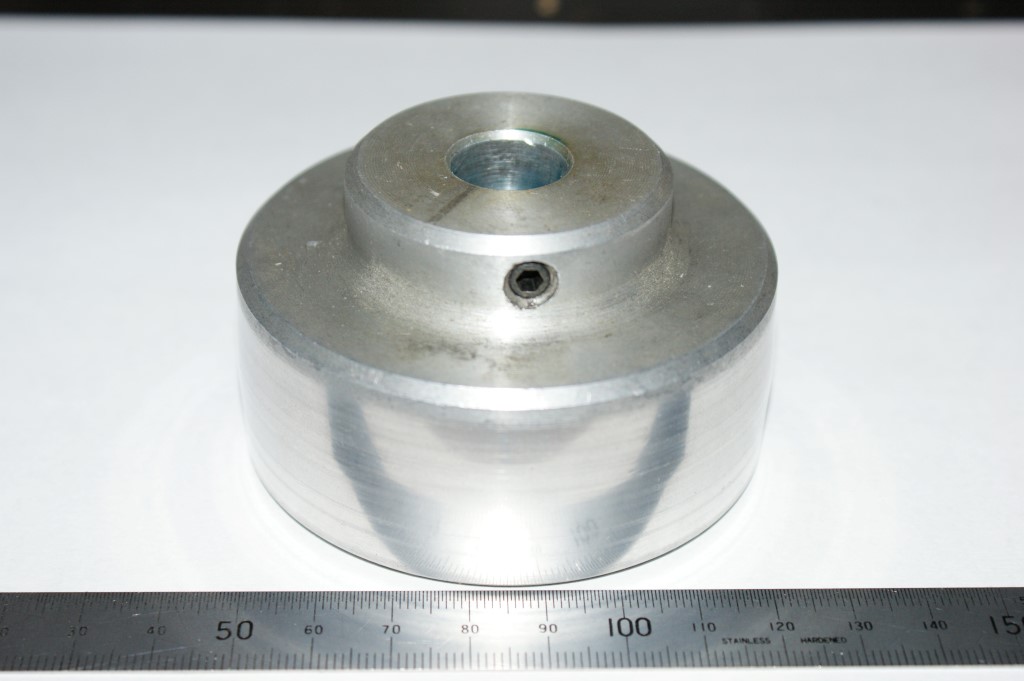

↓ Here are some dimensions and views of the motor pulley.

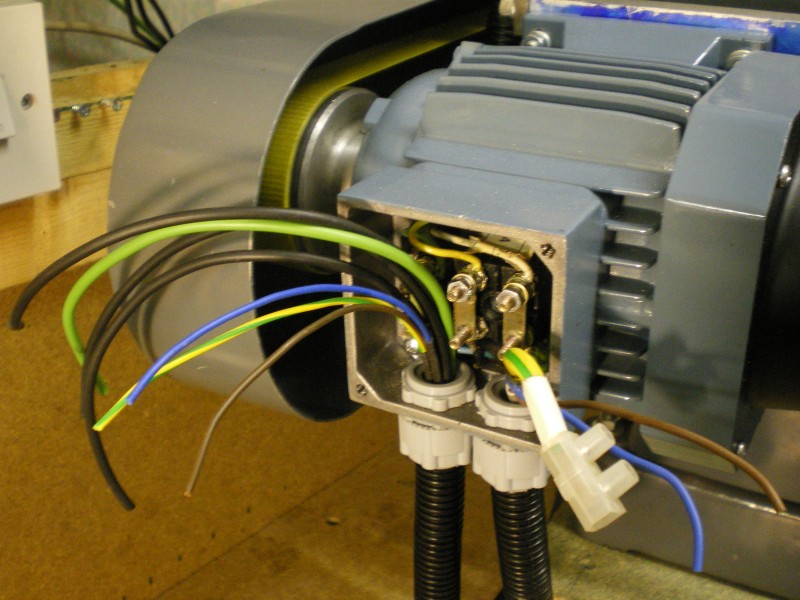

... and fitted two plastic End Fittings for the Plastic Conduit.

The wiring is enclosed in black Plastic Conduit.

Here you can see the 3 Phase supply wired in Delta. The three metal links connect the top three terminals with the bottom 3 terminals (U V W).

I crimped Bullet Connectors on the ends of the MEM Lamp supply cables, and joined them up in the Motor Cable Box.

The wiring at the motor was completed.

Here is the Plastic Conduit entering the Mem Lamp.

↓ The wiring is all straightfoward.