| MILL DEPTH STOP |

| WMT300/2 (similar to the Clarke, Grizzly 4015 and Smithy 1220) |

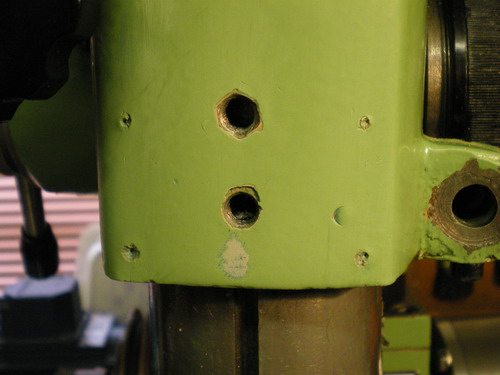

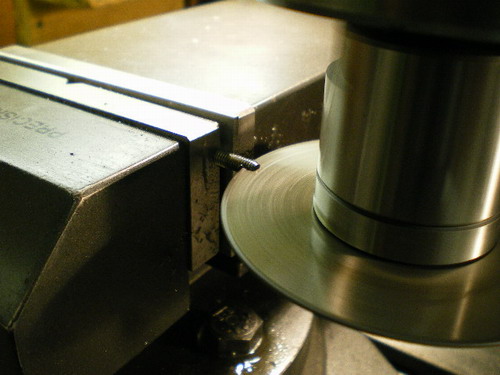

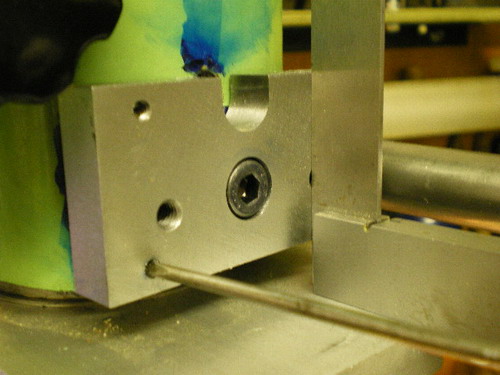

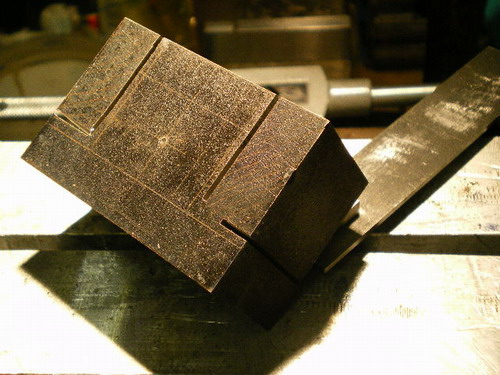

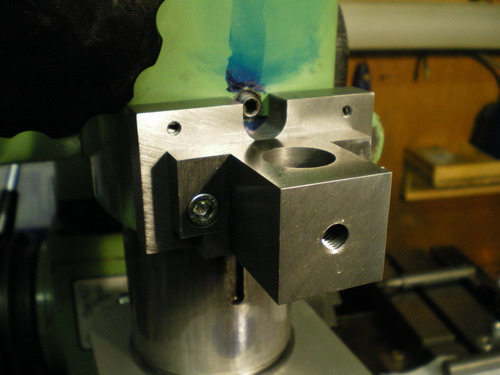

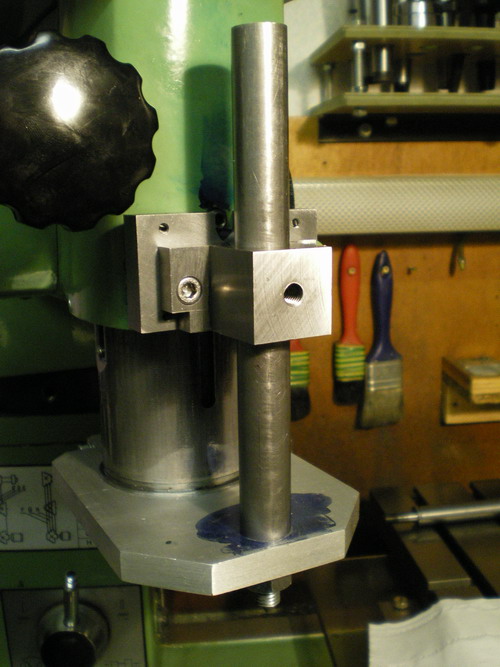

↓ The base plate fouls the existing M8 quill lock hole, so a U channel is milled.

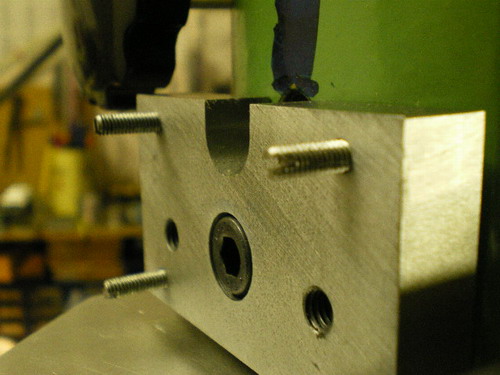

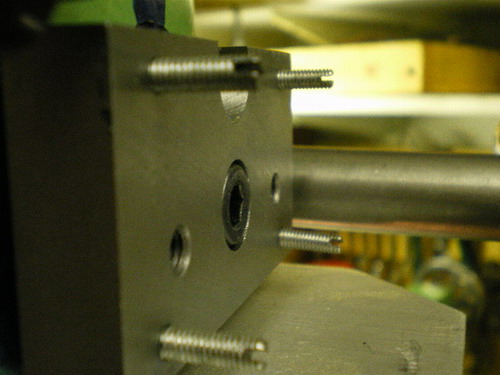

↓ The four adjuster screw holes are drilled and tapped M4.

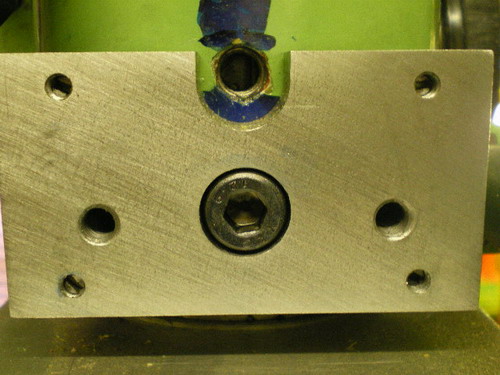

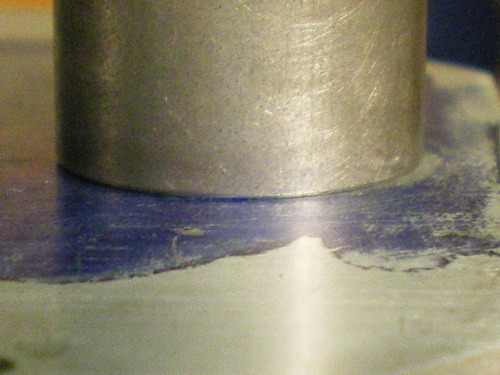

↓ That cap head is standing a little proud. I will mill a little off the cap head later.

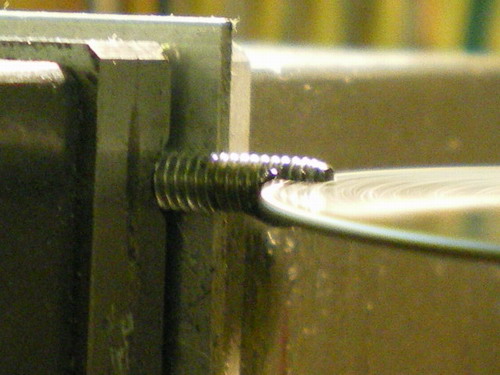

↓ Here are the screws after slotting. I made an extra one.

↓ Here are the screws after finishing in the lathe.

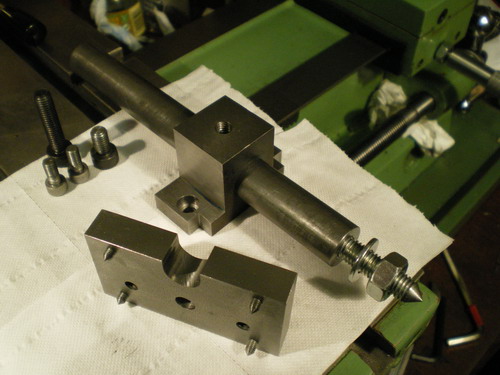

↓ The adjuster screws are inserted in the plate.

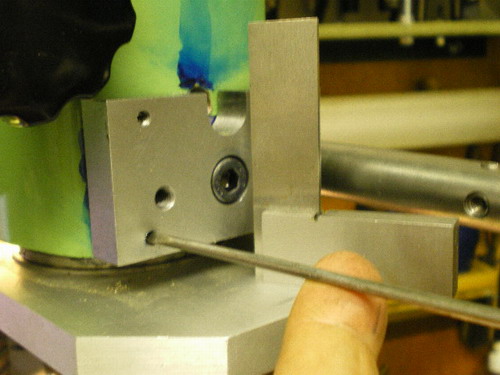

↓ The base plate is lined up to the quill nose plate using a set square and a screwdriver on the adjusters.

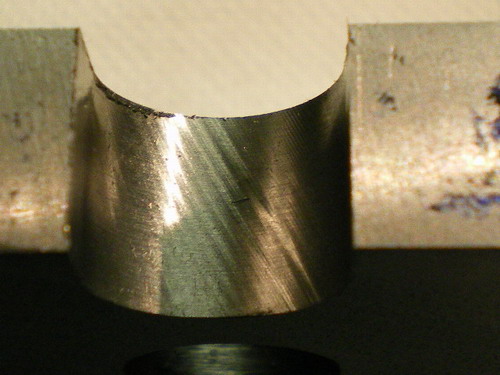

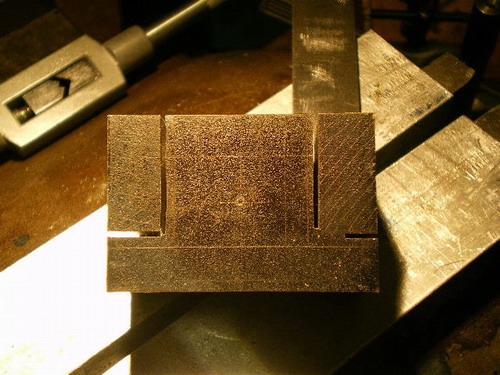

↓ I bored the hole to 19mm (3/4"), then made the final cuts.

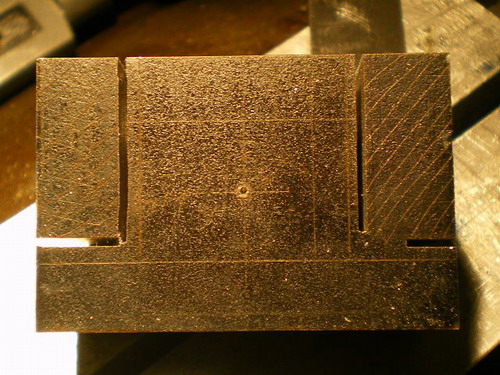

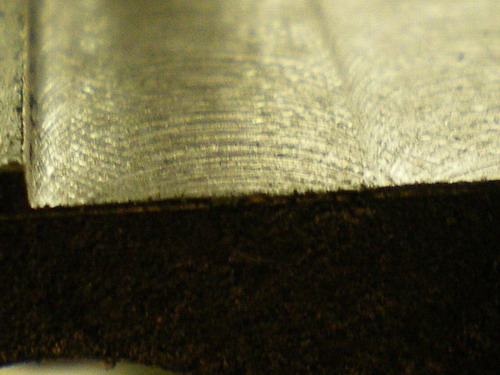

↓ The top was trued up with a fly cutter.

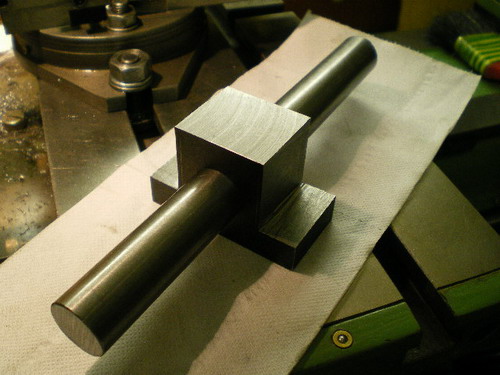

↓ The depth stop rod was tested in the bore.

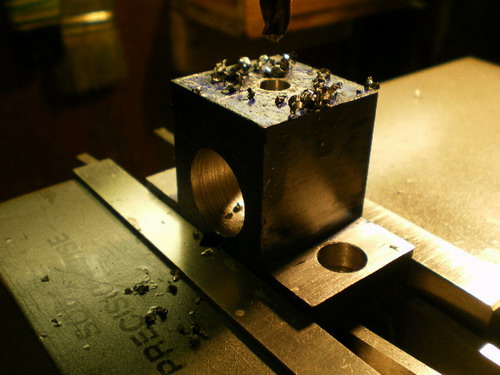

↓ The sides of the block were milled to the lines with an end mill.

↓ The top of the block was drilled and tapped M8.

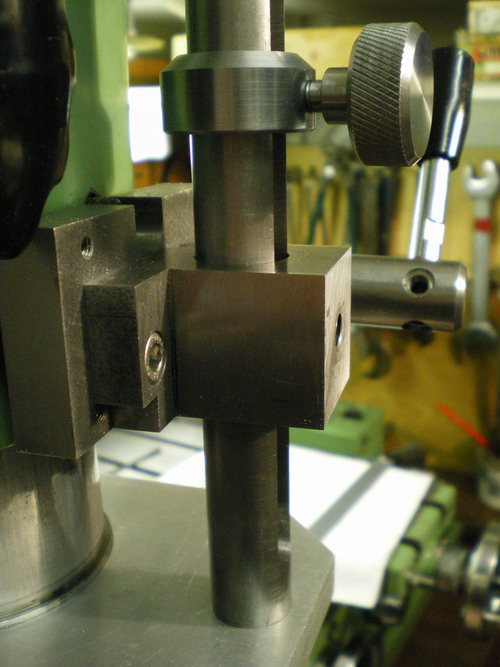

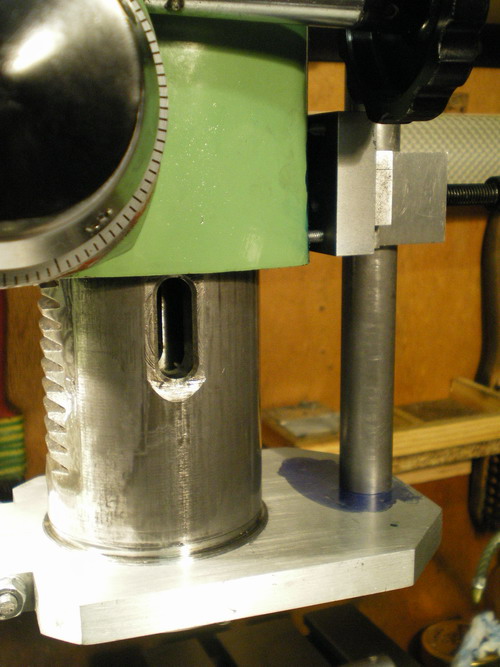

↓ Note the access to the original quill lock.

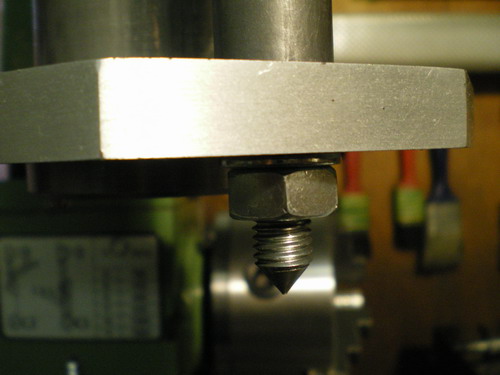

↓ I drilled and tapped the depth stop rod for an M10 stud. I put a point on the stud, and it helped to mark the hole position on the quill nose plate.

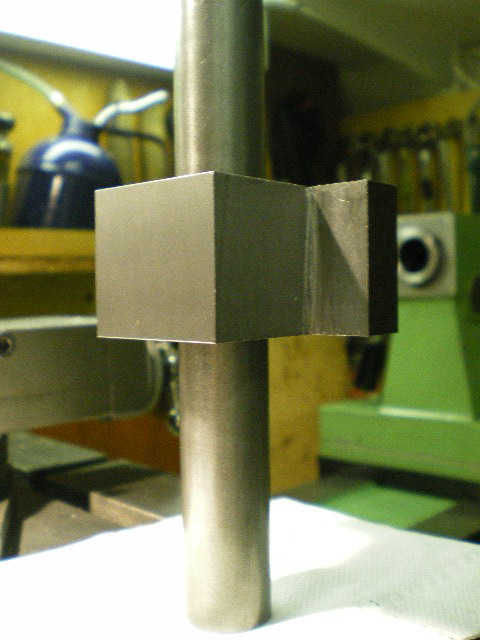

↓ The depth stop rod lines up with the quill nose plate quite nicely.

↓ The depth stop rod attached to the quill nose plate.

↓ The 19mm diameter depth stop rod, quill, and quill nose plate all move up and down without any binding or slop. I am pleased about this.

↓ This shows the gap behind that base plate. Note the adjuster screw.

↓ The M8 cap screw can be used to lock the depth stop rod, and hence help lock and steady the quill.

↓ Here is a close up of the locking collar and thumbscrew.

↓ Here are the installed components.